Tolerances of Plastic Components

Plastics are subject to different physical laws than metals.

The up to 10-fold greater thermal expansion, the change in volume due to moisture absorption and subsequent dimensional changes due to the reduction of residual stresses in the long-term behavior preclude the guarantee of close dimensional tolerances. Components made of plastic should therefore be toleranced differently from components made of metal.

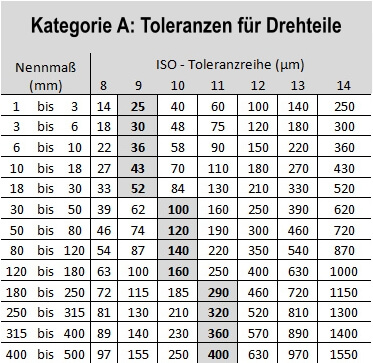

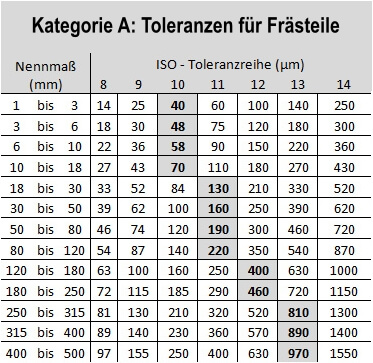

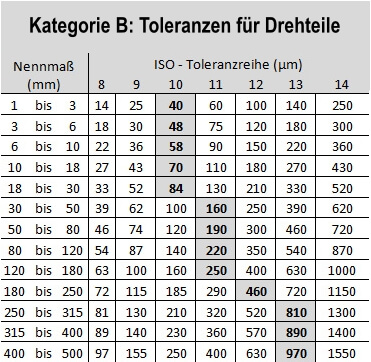

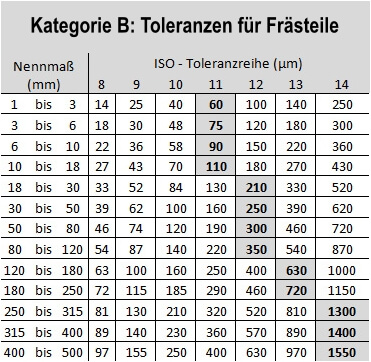

With the tolerance classes specified in the DIN ISO 2768 standard, the function of the plastic part is generally guaranteed. If tighter tolerances are required, the plastic category but also the machining form must be taken into account, see tables below. Even tighter specifications are to be discussed with our machining specialists in a case-by-case examination.

DIN ISO 2768-1

| Tolerance class | up to 6 mm | 6 to 30 mm | 30 to 100 mm | 100 to 300 mm | 300 to 1000 mm |

|---|---|---|---|---|---|

| f (fine) | +/- 0,05 | +/- 0,1 | +/- 0,15 | +/- 0,2 | +/- 0,3 |

| #m (medium) | +/- 0,1 | +/- 0,2 | +/- 0,3 | +/- 0,5 | +/- 0,8 |

| c (coarse) | +/- 0,2 | +/- 0,5 | +/- 0,8 | +/- 1,2 | +/- 2 |

| v (very coarse) | +/- 0,5 | +/- 1 | +/- 1,5 | +/- 2 | +/- 3 |

DIN ISO 2768-2

General tolerance for straightness and flatness

| Tolerance class | up to 10 mm | 10 to 30 mm | 30 to 100 mm | 100 to 300 mm | 300 to 1000 mm |

|---|---|---|---|---|---|

| H | 0,02 | 0,05 | 0,1 | 0,2 | 0,3 |

| #K | 0,05 | 0,1 | 0,2 | 0,4 | 0,6 |

| L | 0,1 | 0,2 | 0,4 | 0,8 | 1,2 |

General tolerance for squareness

| Tolerance class | up to 100 mm | 100 to 300 mm | 300 to 1000 mm |

|---|---|---|---|

| H | 0,2 | 0,3 | 0,4 |

| #K | 0,4 | 0,6 | 0,8 |

| L | 0,6 | 1 | 1,5 |

General tolerance for symmetry

| Tolerance class | up to 100 mm | 100 to 300 mm | 300 to 1000 mm |

|---|---|---|---|

| H | 0,5 | 0,5 | 0,5 |

| #K | 0,6 | 0,6 | 0,8 |

| L | 0,6 | 1 | 1,5 |

* This material is a registered trademark of Mitsubishi Chemical Advanced Materials.

Your contact person

-

Klaus Prior

Quality Management Officer Quality assurance and scheduling- +49 2992 9760 25

- +49 2992 9760 20

- k.prior@kuhn-marsberg.de