Quality Management

In 2009, the company Kunststofftechnik Kuhn GmbH was certified according to DIN EN ISO 9001:2008 for the first time. Regular successful monitoring and repeat audits confirm the high quality striving and thinking.

In 2024, recertification according to DIN EN ISO 9001:2015 was successfully carried out.

The basis for a functioning quality management system is clear management, a high level of quality awareness among all employees, and constant checks before, during and after production. This represents an important component of our competitiveness and ensures the fullfillment of our customers’ high quality requirements. It goes without saying that we prepare initial sample test reports, works certificates as well as test reports at the customer’s request.

Download the ISO certificates

Steps of Quality Assurance

-

1. Material

We purchase our high-quality engineering plastics directly and exclusively from the market-leading semi-finished product manufacturers. This guarantees high material quality and availability. Materials with approvals, such as: FDA, REACH, RoHS or according to Regulation (EU) No. 10/2011 are available from stock.

-

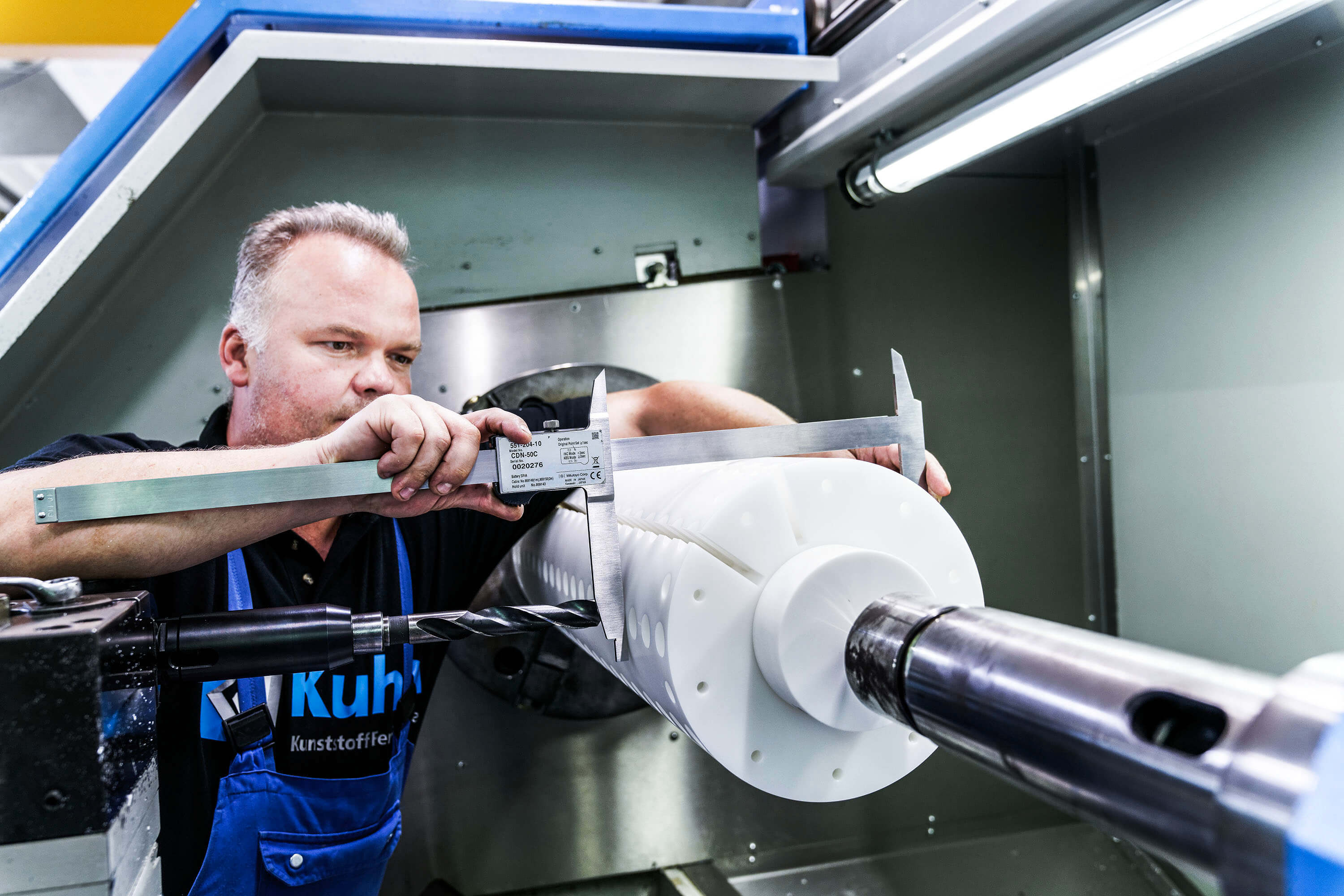

2. Production

During the manufacturing process, constant quality controls are carried out and recorded by our specialized personnel and our QA staff at the machines.

-

3. Final inspection

For the final inspection, our three QA employees have modern testing equipment at their disposal, in addition to their great expertise and many years of experience. This is the basis for a detailed inspection and documentation.

Quality Assurance

The testing of the high-quality prefabricated plastic parts is carried out separately in a climate-controlled measuring room, at a constant ambient temperature of 20°C. This ensures accurate, comparable and meaningful testing.

2D Height Gauge

- 1D and 2D measurements

- Tolerance monitoring

- Straightness measurements

- Angle calculation

- Measuring programs

Image guided 3D coordinate measuring machine

- 3D measurements

- Measurement of shape and position tolerances

- Tolerance monitoring

- Determine coordinate systems

- Measuring programs

Tolerances on Machined Plastic Components

Plastics are subject to different physical laws than metals

The up to 10-fold greater thermal expansion, the change in volume due to moisture absorption and subsequent dimensional changes due to the reduction of residual stresses in long-term behavior preclude the guarantee of close dimensional tolerances.

Your personal contact

-

Klaus Prior

Quality Management Officer Quality assurance and scheduling- +49 2992 9760 25

- +49 2992 9760 20

- k.prior@kuhn-marsberg.de

-

Michael Thielemann

Quality Assurance Officer Quality assurance- +49 2992 9760 27

- +49 2992 9760 20

- m.thielemann@kuhn-marsberg.de

-

Gisbert Schröder

Deputy Quality Assurance Officer Quality assurance- +49 2992 9760 31

- +49 2992 9760 20

- g.schroeder@kuhn-marsberg.de